In the modern automotive landscape, we are constantly told that “displacement is dead.” We are ushered toward a future of tiny, highly-stressed turbocharged engines that look fantastic on a window sticker but often crumble before the second owner can finish their loan payments. For the high-mileage enthusiast, these complex machines can feel less like engineering marvels and more like ticking financial time bombs.

However, if you look past the marketing brochures and into the service bays of master mechanics, a different story emerges. To find the “forever” car in 2026, we must look at the Mechanical Immortals, an elite club of engines over-engineered to the point of absurdity. By studying these legends, we discover that durability is not accidental. It is a specific DNA that modern manufacturers are only now beginning to rediscover.

The “secret sauce”: The three pillars of mechanical immortality

To understand why certain engines reach the half-million-kilometers mark while others fail at 100,000, we have to look at the physics of the engine block itself. Durability in the automotive world is rarely about “new” features; it is about how an engine manages three fundamental enemies: Heat, Friction, and Pressure.

While modern engines often prioritize weight reduction at the expense of longevity, the “Secret Sauce” of a legendary engine usually boils down to three core engineering philosophies:

- Cast Iron Construction: Most “immortal” engines utilize cast iron for both the block and the cylinder head. While heavy, iron is the king of thermal stability. It handles “heat cycles”, the constant expansion and contraction of an engine as it warms and cools, far better than lightweight aluminum. It is significantly less prone to warping or cracking when the cooling system is neglected. Much of the metallurgy we see today was perfected on the track before hitting the showroom floor. You can see this evolution in our deep dive into how race car innovations revolutionized road cars.

- Low “Specific Output”: The greatest killer of an engine is stress. “Specific output” refers to the horsepower an engine produces per liter of displacement. The immortals kept this number low. For example, the Ford 300 is a massive 4.9L engine that only produced ~150 hp. Because it was not working hard to move the vehicle, the internal components (bearings, journals, and pistons) were never under significant pressure.

- Under-Square Design (The “Long Stroke”): Most high-performance engines are “Over-Square” (wide bore, short stroke) to achieve high RPMs. Durable engines are the opposite. An Under-Square design features a “long stroke,” where the piston moves a long distance up and down. This creates massive torque at low RPMs, meaning the engine does not have to “scream” or rev high to get the job done, drastically reducing frictional wear over decades.

The hall of immortals: 9 engines that refuse to die

With these principles in mind, we can look at the “Hall of Fame.” These eight engines did not just meet the standards of their day; they redefined what a consumer product was capable of achieving. They are the benchmark against which all modern reliability is measured.

1. Ford 300 Straight-Six (1965–1996)

Often called “The Anvil,” the Ford 300 is the backbone of American utility.

- The tech secret: It is one of the few engines in history with no timing belt or chain. Instead, it uses Timing Gears, massive metal gears mashed directly together. There is no “wear item” to snap or stretch. As long as there is oil, the timing is permanent.

- The build: With seven main bearings and a cast-iron head, it was designed for trucks, tractors, and industrial generators. It is common to see these engines outlive three different truck chassis.

2. Mercedes-Benz OM617 Diesel (1974–1991)

The “Million-Mile Engine” that powered the legendary W123 Mercedes-Benz taxis across the globe.

- The tech secret: It is a low-stress, 5-cylinder diesel with zero complex electronics. The fuel injection system is purely mechanical. In fact, these engines are so robust that if the car’s entire electrical system failed while driving, the engine would continue to run indefinitely as long as it had fuel.

3. Toyota 22R / 22R-E (1981–1995)

The engine that made the Toyota Hilux and 4Runner global legends for indestructibility.

- The tech secret: A massive cast-iron block and an incredibly simple SOHC (Single Over-Head Cam) design. Toyota focused on cooling and low-end grunt rather than top-end speed.

- The legend: This is the engine that famously survived Top Gear’s attempts to kill it, including placing the truck on top of a 240-foot building before it was demolished. The engine started with basic tools and no spare parts.

4. Chrysler “Slant Six” (1959–1991)

Affectionately known as the “Leaning Tower of Power.”

- Fascinating fact: The engine was tilted 30 degrees to the side to allow for a lower hood line. However, this tilt accidentally created room for a “Long Runner” intake manifold. This made the engine incredibly efficient at breathing, creating a smooth power band that allowed it to stay in production for over 40 years with almost no major changes.

5. Toyota 1UZ-FE V8 (1989–2000)

The engine that launched the Lexus brand and sent shockwaves through the German luxury industry.

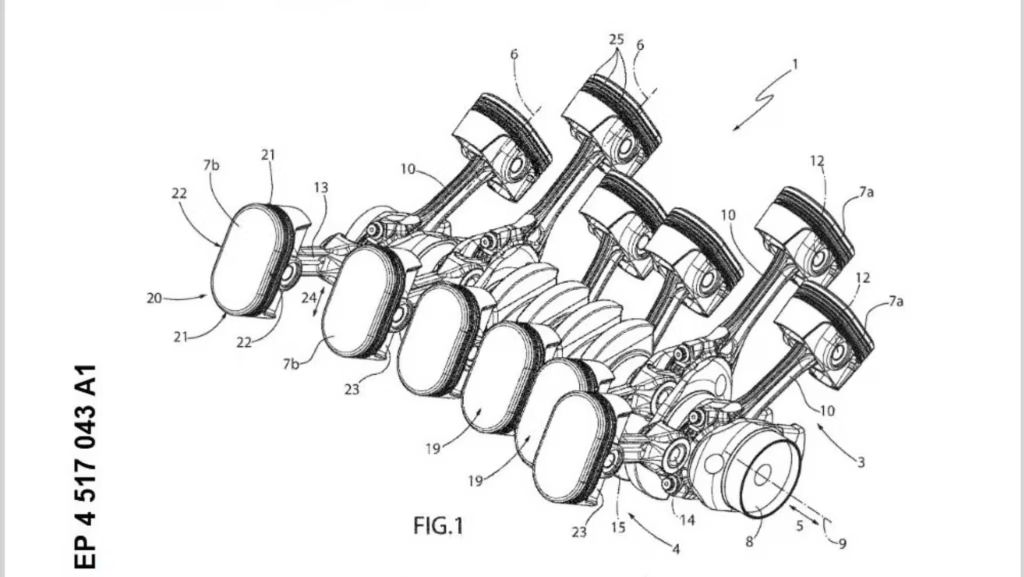

- Fascinating fact: When Toyota designed the first Lexus LS400, they spent $1 billion on R&D. The 1UZ-FE was so vibration-free and over-engineered that it was certified by the FAA for use in airplanes. It remains one of the only road-car engines to ever be legally cleared for flight. The 1UZ-FE proved that a V8 could be as smooth as silk through sheer precision. Today, that pursuit of multi-cylinder perfection continues with even more exotic configurations, such as the recently patented W12 engine from Porsche, which seeks to push the boundaries of packaging and power density.

6. Jeep (AMC) 4.0L Straight-Six (1986–2006)

The American workhorse of the Cherokee (XJ) and Wrangler (TJ).

- The tech secret: This was a “dinosaur” engine in the best way possible, a cast-iron, pushrod design that could handle extreme heat and oil neglect. Its Non-Interference design meant that even if the timing chain failed (which it rarely did), the pistons would never hit the valves, preventing a total engine meltdown.

7. General Motors 3800 V6 (Series II)

One of the best V6 engines ever made, powering tens of millions of Buicks and Pontiacs.

- The tech secret: GM perfected the “Pushrod” V6 here. By avoiding complex overhead cams and dozens of sensors, they created a simple, high-torque engine where the only common failure point was an inexpensive plastic intake manifold. The rotating assembly itself is essentially bulletproof.

8. Volvo “Redblock” (B18 / B20 / B230)

The engine that defined the “Boxy but Good” Swedish reliability.

- The record: A 1966 Volvo P1800 with the B18 engine holds the Guinness World Record for the highest mileage on a personal vehicle at 3.2 million miles.

- The tech secret: These engines used exceptionally thick iron blocks designed to survive Arctic Swedish winters, where oil flow is slow, and metal is brittle.

9. Honda K-Series (2001–Present)

You cannot talk about modern reliability without the Honda K20 and K24. This engine proved that a high-revving four-cylinder could still be a “forever” engine.

- The tech secret: It features an incredibly stiff block with cast-iron cylinder sleeves and a forged steel crankshaft. Its oiling system is so efficient that even under high-RPM VTEC crossover, the bearings remain perfectly lubricated.

- Legacy: It replaced the legendary B-series and became the go-to engine swap for anyone wanting 300hp and 300,000-kilometer reliability in the same package.

The great correction: How the “Ghost” returns in 2026

It is easy to look at the list above and assume that “they do not build them like they used to.” For a while, that was true. During the early 2000s, many brands sacrificed this legendary durability in favor of complex sensors and plastic components.

However, we are currently witnessing a “Great Correction.” Leading manufacturers have realized that the physics of the 1960s, the “Ghost in the Machine”, cannot be ignored. By modernizing the philosophies of the Ford 300 and the Slant-Six, they are creating a new generation of immortals.

The return of the long stroke

If you look at the specs for the Toyota 2.5L Dynamic Force or the Mazda Skyactiv-G, you will notice their stroke is significantly longer than their bore. This is a direct copy of the Ford 300 philosophy. By returning to this “Under-Square” geometry, modern engines can achieve high thermal efficiency and low-end torque without needing a small, high-stress turbocharger to “make up” the power.

This return to reliable, driver-focused engineering is even reviving the sports coupe segment. A prime example is the 2026 return of the Honda Prelude, which promises to blend modern efficiency with the durability fans have missed.

Dual Injection (The direct injection fix)

Modern Direct Injection (DI) creates carbon buildup on intake valves because gasoline no longer “washes” them, a flaw that kills many modern German engines by 100k kilometers.

The Solution: Toyota’s D-4S system brought back “old-school” Port injection to work alongside Direct injection. By re-adopting the fuel delivery method of the 1980s, they keep the valves clean and the engine running for decades.

While we perfect these cycles, some are rewriting the rulebook entirely, like the one-stroke engine, which challenges our traditional understanding of durability.

From heavy metal to precise machining

The Toyota 1UZ-FE proved that “complexity does not equal failure” if the precision is high enough. Modern “immortals” use laser-guided assembly and high-pressure die casting to ensure that parts fit with zero “slop,” reducing the internal friction that leads to engine death.

Rethinking the Piston

While traditional round pistons and long strokes remain the gold standard for longevity, the high-performance world is looking at radical new shapes to manage internal stress. Ferrari, for example, is exploring oval piston V12 engine technology to maximize valve area and improve combustion efficiency, a high-tech evolution of the “breathing” principles found in the Slant-Six.

The blacklist: The high cost of cutting corners

While some have learned from the past, others serve as cautionary tales. These five engines represent the opposite of durability, designs where “paper specs” and cost-cutting were prioritized over real-world physics. If you are shopping for a used vehicle, these are the engines that failed to follow the rules of the Immortals:

- Chrysler 2.7L V6 (1998-2010): Narrow oil passages caused “Oil Sludge” that seized engines prematurely. It lacked the thermal management of the old iron blocks.

- GM 2.4L Ecotec (2010-2017): Notorious for massive oil consumption and timing chain failure that totaled cars before 100k kilometers.

- Ford 1.5L/1.6L EcoBoost: Suffered from “Coolant Intrusion,” where a block design flaw allowed coolant to leak into the combustion chamber, cracking the block.

- BMW N63 (V8): The “Hot V” design placed turbos in the center of the engine, baking the rubber and plastic components until they crumbled.

- Cadillac Northstar V8: A disaster of metallurgy where steel head bolts would pull out of the aluminum block, making head gasket failure a certainty.

The Tech-nically buyer’s checklist

The journey from the cast-iron slabs of the 1960s to the high-compression alloys of today shows us that durability is a choice. If you are looking for your next 300,000+ kilometers companion, here is the ultimate cheat sheet:

- Geometry: Is it Under-Square? (Long stroke = Long life).

- Aspiration: Naturally Aspirated (no turbo) is always the safer bet for 300,000+ kilometers.

- Timing: Does it have a steel timing chain or, better yet, gears? Avoid rubber belts.

- Injection: Does it have “Dual Injection” or “Port Injection”? Avoid “Direct-only” setups to prevent carbon choking.

As we look beyond gasoline, Toyota is already betting on a different kind of longevity with the Toyota Mirai and its hydrogen fuel cell technology. But for the internal combustion engine, the Ford 300 was an anvil, and the modern Toyota is a scalpel. The Ford 300 survived because it was too heavy to break; the modern Toyota survives because it is too precise to wear out. Different eras, different metals, but the same ancient physics of “Low Stress” remain the gold standard for mechanical immortality.