For the world’s best car makers, the electric motor became the new performance ground. Simply fitting a large battery is not enough anymore. Success depends on the EV motor’s Power Density (kW/kg) and System Efficiency. Companies race to create lighter machines that spin faster, and convert more battery energy into forward motion.

We will examine the engineering ideas from major global players. From the hypercar precision of Koenigsegg, the extreme density of Yasa/Mercedes, to the mass-market success of Tesla and the vertical control of Asian giants Xiaomi and BYD.

Understanding the technology of EV motors

But first, how is the EV motor’s power generated? The concept is simple: A motor’s design starts with the direction of its magnetic flux. This magnetic field creates the turning force, called torque.

The simple explanation: How is the motion generated?

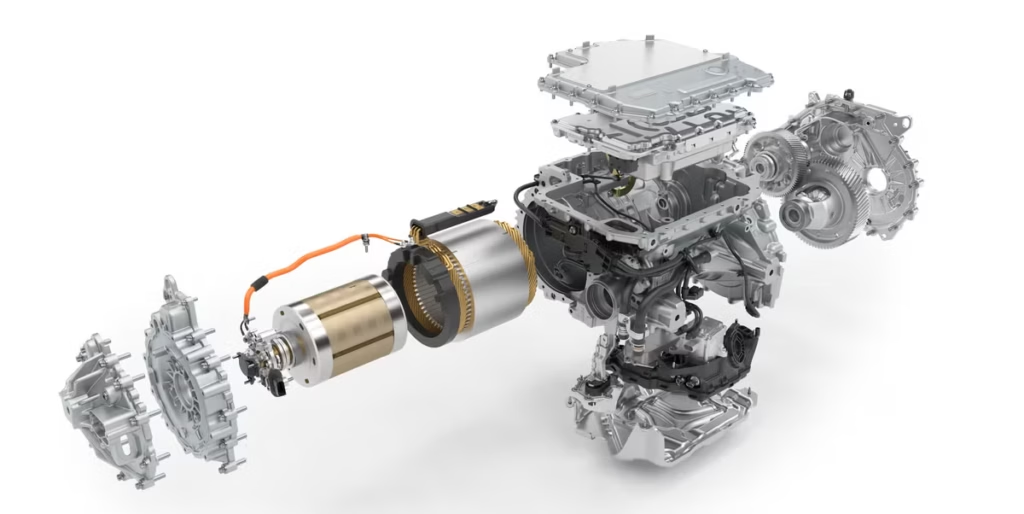

All electric motors use electromagnetism to create rotation. The motor has two main parts: The Stator and the Rotor.

- The Stator is the stationary outer part with wire coils. When electricity flows through these coils, they create a moving magnetic field.

- The Rotor is the inner, rotating part with magnets. The moving magnetic field from the stator constantly pulls and pushes the rotor’s magnets. This causes the rotor to spin fast, driving the car’s wheels.

The technical explanation: Flux direction and design

- Radial-Flux Motors (The Standard): The magnetic flux runs outward from the center shaft, like spokes on a wheel. These motors are cylindrical, easy to make, and work well at high RPMs. Most common EVs from Tesla, BYD, and Xiaomi use different versions of this design.

- Axial-Flux Motors (The New Contender): The magnetic flux runs parallel to the central shaft. This disk-shaped design, sometimes called a “pancake” motor, has a much larger surface area for magnets and coils. This design results in significantly greater torque density and power density compared to the radial-flux design.

Key Metrics for Comparison:

- Power Density (kW/kg): This shows how much power an EV motor makes compared to its weight. It is the best efficiency measure.

- Max RPM: This is how fast the motor spins. It connects directly to the power available at high speeds.

- System Integration: This notes how many components, like the EV motor, inverter, and gearbox, are packaged into one unit. This affects car size and manufacturing cost.

Comparing each car manufacturer’s approach

The major car makers and specialized engineering firms each follow a unique ev motor design plan. Their choices depend on their market goal: extreme hypercar power, cost-effective mass-market range, or breaking RPM limits. This section details the core technology and facts driving the innovation at each key company.

Rimac Nevera: Quad-Motor drivetrain – All-Wheel electric supremacy

| Metric | Detail |

| Type | Four bespoke, surface-mounted, carbon-sleeve Permanent Magnet Synchronous Electric Motors (PMSM) |

| Specs | 1,550 kW (2,107 hp) total power, 2,340 Nm total torque |

| Approach | Distributed power system (one motor per wheel) enabled by Rimac All-Wheel Torque Vectoring 2 (R-AWTV 2). A single-speed gearbox is used for each wheel. The focus is on instant, precisely controlled power delivery to maximize traction and performance. |

| Unique Point | R-AWTV 2 System: Replaces traditional stability and traction control by independently calculating and applying the precise amount of torque to each of the four wheels over 100 times per second. This allows for unparalleled dynamic response, stability, and control, effectively enabling the most advanced form of all-wheel drive. |

Koenigsegg: The Dark Matter – Compact power redefined

| Metric | Detail |

| Type | Raxial-Flux Hybrid (combines Axial and Radial elements) |

| Specs | 600 kW (800 hp), 1250 Nm peak torque, 39 kg dry mass |

| Approach | Focus on Power Density. This motor blends the high torque of axial flux with the high-speed capability of radial flux, up to 8,500 RPM. It uses a special 6-phase power system for smooth power delivery. |

| Unique Point | Extreme Power Density of ~15.4 kW/kg. It is the world’s most powerful car motor based on weight. It replaced three motors in Gemera’s original design with one compact unit. |

Yasa / Mercedes: Axial-Flux efficiency at scale

| Metric | Detail |

| Type | Pure Axial-Flux (Yokeless and Segmented Armature) |

| Specs (Prototype Record) | 750 kW (1,005 hp) from a 12.7 kg motor. Production motors (P400 R) offer 160 kW and 370 Nm. |

| Approach | Uses a proprietary ‘Yokeless and Segmented Armature’ structure. This design significantly cuts down on size and weight. |

| Focus | Scalable, Ultra-Density Efficiency. Yasa holds an unofficial power density world record of ~59 kW/kg with a prototype. This proves the maximum potential of axial-flux technology. Mercedes-Benz is bringing this technology to its high-performance AMG electric cars. |

Tesla: Relentless refinement and control

| Metric | Detail |

| Type | PMSR (Permanent Magnet Synchronous Reluctance) + Induction Hybrid Mix |

| Specs (Model S Plaid) | 305 kW (412 hp) per rear motor, 20,000+ RPM |

| Approach | Balancing mass production needs with a great range and fast acceleration. Tesla utilized Silicon Carbide (SiC) inverters early on to enhance efficiency and manage high electrical loads. |

| Focus | Balancing mass production needs with great range and fast acceleration. Tesla used Silicon Carbide (SiC) inverters early on to boost efficiency and handle high electrical loads. |

Xiaomi: A new tech challenger

| Metric | Detail |

| Type | High-speed PMSM (Permanent Magnet Synchronous Motor) – Radial Flux |

| Specs (HyperEngine V8) | 425 kW (570 hp), 27,200 RPM max speed |

| Approach | Focuses on extreme rotational speed. This maximizes power output from a smaller motor. It achieves this with ultra-strong Silicon Steel Plate and advanced Two-way Full Oil Cooling. |

| Focus | High-speed innovation. Xiaomi uses its tech background to push EV motor RPM limits. It claims the highest speed for a mass-produced electric motor, competing directly with high-end car performance. |

BYD: Efficiency through vertical integration

| Metric | Detail |

| Type | PMSM (Permanent Magnet Synchronous Motor) – Radial Flux |

| Specs (Seal Performance) | 390 kW (523 hp) combined AWD max, ~15,000 RPM (typical e-Platform) |

| Approach | Vertical Integration. The 8-in-1 electric powertrain puts the EV motor, motor controller, gearbox, and five other key components into a single, compact unit. This makes the system cost-effective. |

| Focus | Mass-market efficiency and cost control. The e-Platform 3.0 boasts an overall system efficiency of up to 89%. BYD achieves this by controlling the entire supply chain, from the Blade Battery to the motor. |

How are these EV motors compared to each other?

Comparing the specifications makes each company’s true achievement clear. The table shows the peak performance facts and reveals the different engineering priorities. Rimac and Koenigsegg lead in power density and pure power, and Tesla and Xiaomi focus on rotational speed, RPM, and sheer instantaneous acceleration.

| Brand | Motor Type | Peak Power (kW) | Peak Torque (Nm) | Efficiency | Max RPM | Key Feature |

| Rimac | 4x Carbon-sleeve PMSM | 1,571 kW – 2,107 hp (Total) | 2,340 (Total) | ~ 97% | 17,500 (Est.) | Quad-Motor All-Wheel Torque Vectoring. Designed for the most extreme and sustained track performance. |

| Koenigsegg | Dark Matter Raxial-flux | 600 kW – 800 hp | 1250 | ~ 93% | 8,500 | Highest Production Power Density ~15.4 kW/kg 6-phase technology. (Used in Gemera) |

| Yasa/Mercedes-AMG | Axial-flux (Prototype) | 750 kW – 1,006 hp | N/A (Prototype) | ~ 96% | ~ 8,000 (Est.) | Unofficial World Record Power Density ~59 kW/kg from a 12.7 \ kg motor. |

| Tesla (Plaid) | Tri-Motor (PMSM + Induction) | 760 kW – 1,020 hp (Total System) | 1,420 (Total System) | ~ 92–96% | 20,000+ | Carbon-sleeved rotor for extreme high speed; 3-motor All-Wheel Drive system. |

| Xiaomi (HyperEngine V8s) | High-speed PMSM | 425 kW – 570 hp | 635 | ~ 94% | 27,200 | Highest Mass-Produced RPM globally; 960MPa ultra-high-strength silicon steel plate. |

| BYD | PMSM (8-in-1 System) | 230 kW (Single Rear Motor) | 360 (Single Rear Motor) | ~89% (System) | ~ 15,000 | High-power Cell-to-Body (CTB) battery integration; 8-in-1 compact e-drive system. |

Design philosophy and trade-offs

The different numbers in the table come from different design choices. An EV motor’s final goal depends on the car’s use. This forces engineers to make specific choices about physical design, cooling, and how parts fit together.

Performance vs. Efficiency

- Performance Priority (Koenigsegg, Xiaomi, Rimac): These makers focus on one metric, like power density (kW / kg) or rotational speed (RPM). The goal is maximum output, usually at a higher part cost. Rimac’s approach is to tune its highly efficient EV motors for raw, record-breaking power, prioritizing hypercar acceleration and speed over long-range efficiency.

- System Efficiency Priority (BYD, Yasa/Mercedes): Their focus is on the total system’s efficiency. BYD makes the entire integrated unit better for heat and cost. Yasa builds a highly efficient, small motor that increases a car’s driving range.

Integration vs. Modularity

- Proprietary Integrated System (Rimac): Rimac designs and manufactures nearly all key components (battery, EV motors, inverters) in-house. This vertical integration allows for total system optimization for performance. The battery is an integral, structural part of the carbon-fiber chassis.

- Integration for Cost (BYD): The (8-in-1) single-unit platform is a manufacturing achievement. BYD builds the whole electric drivetrain in one place, which reduces complexity and production cost for the mass market.

- Modularity for Design (Yasa/Mercedes): Axial-flux motors are thin. This allows car manufacturers to fit them into tight spaces on different car platforms without needing large gearboxes.

Thermal Management

- The High-Speed Challenge: EV Motors from Tesla and Xiaomi spin at 20,000 RPM and faster, which creates a lot of heat.

- Solution: All high-performance motors use advanced liquid or oil cooling. Koenigsegg’s Raxial-Flux and Xiaomi’s HyperEngine V8 use complex, high-flow oil systems to manage the heat at peak power and speed. Rimac’s system uses sophisticated liquid cooling for the battery, four motors, and inverters to manage the extreme sustained heat from its record-breaking power output.

Manufacturing Approach

- In-House Boutique Engineering & High-Tolerance (Rimac): Production is low-volume and hand-built. Rimac pushes material and design limits by using a bespoke structural carbon-fiber monocoque (the largest single piece of carbon fiber on a production car) and developing all major powertrain components in-house.

- Boutique Precision (Koenigsegg): This method focuses on low-volume, high-tolerance production. It pushes material and design limits, using parts like carbon fiber and high-grade 300M steel.

- Scale Economy (BYD): This method centers on high-volume production of pre-packaged units. It gains cost control by managing the whole supply chain and using standard parts.

Which EV manufacturer creates the fastest car?

While peak motor metrics are vital, the final car’s performance depends on power management, torque vectoring, and aerodynamics. Hypercar manufacturers leverage every fraction of the motor’s capability to set world records.

| Vehicle (Top Variant) | Total System Power | System Torque | 0-100 km/h (0-62 mph) | Max Speed |

| Rimac Nevera R (BEV) | 2,107 hp (1,571 kW) | 2, 340 Nm | 1.72 seconds | 430 km / h (267 mph) |

| Koenigsegg Gemera V8 (PHEV) | 2,300 hp (1,715 kW) | 2,750 Nm | 1.9 seconds | ~400 km/h (249 mph) (for I3 variant, V8 variant is expected to be similar or higher) |

| Tesla Model S Plaid (BEV) | 1,020 hp (760 kW) | 1,420 Nm | 2.1 seconds | 322 km/h (200 mph) |

| Mercedes-AMG Concept AMG GT XX (BEV) | >1,360 hp (>1,000 kW) | Not officially published | ~2 seconds | >360 km/h |

| Xiaomi SU7 Ultra (BEV) | 1,548 PS (~1,138 kW) | Not officially published | 1.98 seconds | 350 km/h (Designed) / 359.71 km/h (Tested) |

| BYD Yangwang U9 Xtreme (BEV) | >3,000 PS (>2,220 kW) | Not officially published | Not officially published (Standard U9: 2.36 s) | 496.22 km/h |

The future of high-performance EVs

The global race for electric power is no longer solely about battery size. It is fundamentally about the electric motor’s engineering integrity. As seen in the contrast between Koenigsegg’s record-setting 15.4 kW/kg power density and Xiaomi’s extreme 27,200 RPM motors, manufacturers are pursuing distinct paths to performance.

The future points to the wide-scale adoption of axial-flux technology (championed by Yasa/Mercedes for its efficiency) and the universal migration to 800V/1000V high-voltage platforms (pioneered by Tesla and integrated by BYD). Ultimately, success will be defined not by a single metric, but by the integration of the entire powertrain, from the chemical cell and the sophisticated SiC inverter to the final, highly efficient, and impossibly fast rotating motor.

While motor efficiency is reaching its peak, the real bottleneck remains energy storage. To see how the next generation of power cells will fuel these high-output motors, read our deep dive into the first production solid-state battery for EVs.

While industry giants are pushing the boundaries of power density, a new wave of engineering is focusing on a different metric: serviceability. The ARIA modular electric car takes a radical approach, utilizing a drivetrain designed to be accessed and repaired in minutes rather than hours, proving that advanced doesn’t always have to mean inaccessible.